Engineered for Efficiency

Machine building and automation of tasks for OEMs helps drive efficiencies, accuracy and innovation in the production cycle. This can directly lead to improvements in quality and consistency of output by replacing labour intensive or laborious tasks.

TPS has a unique offering, working closely with clients to develop concepts for new machines or upgrade existing ones. Whether you’re looking to build entirely new systems from scratch or transform old machines, we come up with the correct solution for your needs.

Capabilities

Our software and machine capabilities are second to none. At our manufacturing base in Dromcollogher, Co. Limerick we practise what we preach – machines operate ‘live’ and in real-time, issuing notification updates by email, text or on-screen pop-ups on changes to machinery or ancillary devices in relation to stoppages or irregular behavioural patterns.

Live data informs key metrics such as machine status, cycle times, efficiency, OEE, stock count and maintenance schedules. We have reduced manual tasks to a minimum, automating and optimising many of the production processes within our warehouse.

We have developed and implemented our own production management system (MaHaSy) in line with customer needs. This allows us to effectively manage incoming volume production orders and deliver components on time with very short lead times.

Our Machine Building and Automation Capabilities

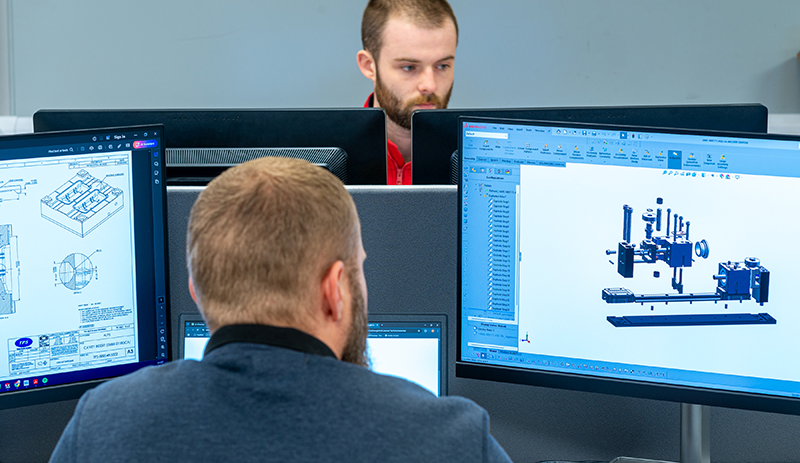

Design

Our design capabilities transform your ideas into precise, innovative solutions. From concept to final machine, we ensure every detail meets your specifications.

Machine Build

Build the machine from scratch or change an existing machine, e.g. hydraulic to electric. This can include the steel frame, electrics and services. The entire machine is created and then sent to the customer, ready to go.

Support

We offer comprehensive support for maintaining, upgrading and enhancing machines over time, ensuring efficiency and longevity.

Get in Touch

We’ve got your design, tooling and automation needs covered.