Preserving Your Precision Assets

TPS understands that proactive tool maintenance is the defining element in sustaining production without interruption and ensuring continuing part-to-part quality.

Our full-spectrum services in tool maintenance help you keep your valuable tooling assets in top working condition and avoid unscheduled downtime, hence maximising the useful life of your equipment.

Proactive Tool Maintenance Solutions

While others offer reactive tool repair, our program in maintenance is truly preventive. We work hard so that your tools are always at their best for whatever your production goals might be.

Why Choose TPS for Tool Repair?

Our Tool Maintenance Process

- Initial Assessment: We assess your tools and create a personalised maintenance program for them.

- Regular Inspection: Regularly scheduled tests to reveal wear and tear.

- Preventative Measures: On-time adjustments, cleaning and replacement of parts to keep it performing.

- Performance Optimisation: Fine tuning makes sure your tool performs at the best.

- Detailed Reporting: We keep you informed with comprehensive maintenance logs and recommendations.

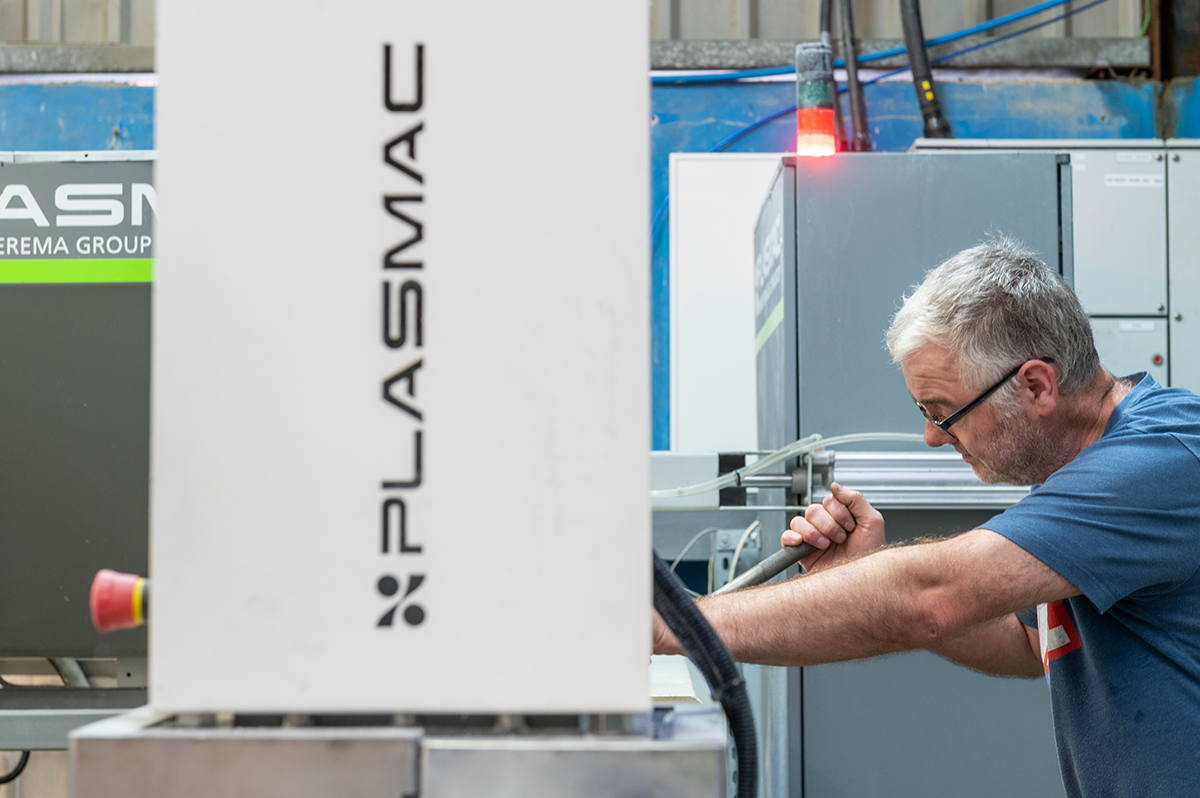

State-of-the-Art Maintenance Facilities

Our full-time maintenance facility is fully equipped with the latest technology for optimum tool care:

- Advanced diagnostic equipment

- Precision cleaning systems

- Specialised tools for a wide range of tool maintenance

Beyond Maintenance: Continuous Improvement

We don’t just maintain your tools; we help them evolve. Our team of specialists can recommend upgrades and modifications based on your unique production requirements to optimise tool functionality and extend its useful life.

Your Partner in Excellence in Production

With TPS, we go above being a service provider. We’re your strategic partner for maintaining production efficiency. With us taking care of tool maintenance, you guarantee that your operations will remain smooth, effective, and competitive.

The TPS Difference: Seamless Maintenance

We know how tool maintenance can be a nagging issue for any manufacturing business. That’s why we built our services to make life as seamless and stress-free as possible:

- Tailor-Made Schedules: We accommodate your production schedule to minimise disturbances

- Clarity in Communication: Continuous feedback along all steps of maintenance

- Speedy Turnaround: Our streamlined procedures minimise the time your tools spend away

- Total Documentation: Full maintenance history for your records and quality control

Never allow tool wear to slow you down or give up your part quality. Partner with TPS for proactive tool maintenance and take comfort in knowing your precision assets are in expert hands. Let us take care of the tools so that you can drive your business forward.

Get in Touch

Schedule your tool maintenance consultation today!